Elka Water PTH

PTH ELKA WATER IMPROVER

What is PTH and how does it work?

PTH stands for Protection against Total Hardness.

Elka PTH Water Improver is a device as the name suggests, a "water improver" but not a softener or a filter. This Water Improver is made of two parts, a cylinder made from stainless steel and an inner core made from an alloy of noble and semi-noble metals. The device is installed on your water line immediately after the water-meter, and is connected to the earth grounding.

The device are combinations of micronic disk cartridge and the water improver device. When water flows through the improver, weak electric fields are produced by electric potential difference between the unique alloy core and the metallic cylinder. These field and the venturic effects stemming from the unique configuration of the core prevent the adhesion and cohesion of the waterborne mineral particles (mainly carbonic salts, calcium and magnesium).

These electro and hydrodynamic forces separate the molecules (especially aluminum and silica) which bind mineral particles. Thus the mineral particles flow through the water system without being precipitated and with no interference. The Elka Water Improver core alloy is nonferrous, highly resistant to rusting and corrosion, non toxic and ecologically safe.

Basically, the PTH ‘scrubs’ the water. This is a completely natural process and occurs freely in nature when, for example, a stream or river flows over a bedrock containing just 2 or more different types of metals or noble or semi-noble minerals. It is an entirely ‘green’ product which will not harm the environment; in fact, it is good for it.

-

What is also important is that when the PTH treats water, mineral salts such as calcium and magnesium remain in the water to benefit the people using the water but, as they are rendered harmless, they do not cause problems in their household appliances or geysers. And, like a natural stream, the taste is improved.

- The PTH system requires no maintenance [other than a quick brush with a wire brush every 9 months or so (the inner core is easy to remove and re-insert)], needs no chemicals, uses no electricity or any other power source and will last a lifetime. In other words, it is a once-off cost…forever.

- Users will enjoy lifelong service from the PTH, with no chemicals, no electricity and the barest of maintenance.

It is also unbreakable. PTH is endorsed by Stellenbosch University, UCT, North West University (Potchefstroom), Ben-Gurion, the Protea Hotel Group, Spilhaus, Witzenberg Irrigation and countless leading institutions and captains of industry in South Africa and world wide, of which a few include Samsung, Kelly Marine, Anglo-De Beers, Polyoak, Sanlam, Marlin Granite and Naspers. - The PTH comes in different sizes. The correct size depends on the water flow rate. It is measured in liters per minute – contact us for the size. It comes with full installation instructions, and is straightforward and easy to install.

How It Works

The working principle behind the PTH anti-scaling in-line catalyst is not to remove Ca2+ or CaCO3, it simply stops CaCO3 (or MgC03) from forming, thus preventing calcium (Ca) and/or magnesium (Mg) from making a solid, stubborn scale that regularly breaks geyser elements, fouls up pipes and requires a 10% increase in power consumption for every millimeter of scale formed on a heating element.

The working principle behind the PTH anti-scaling in-line catalyst is not to remove Ca2+ or CaCO3, it simply stops CaCO3 (or MgC03) from forming, thus preventing calcium (Ca) and/or magnesium (Mg) from making a solid, stubborn scale that regularly breaks geyser elements, fouls up pipes and requires a 10% increase in power consumption for every millimeter of scale formed on a heating element.

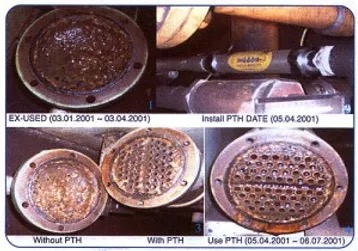

After passing through the PTH catalyst, the “kalk” will either stay as very fine particles suspended in the water or, if already solidified, settle out as a flaky, easily dislodged scale. This happens typically when the PTH removes or cleans a toilet cistern, where the built-up scale flakes off from the sides of the cistern and settles on the bottom.

The 7 Advantages of ELKA Water PTH

1. PRICE:

PTH is considerably cheaper

2. MAINTENANCE:

PTH requires practically no maintenance. Resin softeners cannot function without regular salt charging.

3. RUNNING COSTS:

PTH has no parts to be replaced, and therefore absolutely no maintenance costs. Resin in other softeners age and have to be replaced. Valves in other softeners are volatile and can be problematic. PTH on the other hand, has no moving parts.

4. ENVIRONMENTAL FRIENDLINESS:

Salty discharges released from resin softeners end up in the soil during the brine rinse process, causing brackness, and “nothing” grows in brack soil. Resin softeners have already been banned in several places worldwide. PTH, on the other hand, stimulates crops – up to 200% increase in crop yields.

5. COMFORT:

Easy installation. In-line. Sturdy, practical device. No moving parts. Unbreakable. Eliminates chemicals. Power interruptions confuse rinse cycle in other fully automatic resin softeners – they cannot operate without electricity.

6. SAVINGS:

PTH saves on chemicals, acids, shutdowns, downtime, and manpower, all factors which affect production and consequently, profitability – this applies to plants and factories. Numerous concerns already cancelled costly “contracts” with chemical companies having used PTH for the first time. PTH uses no electricity, apart from being unbreakable and lasting indefinitely. (Resin softeners make water more corrosive.)

7. Safety and Transport

Certain factories process foods, syrups, juices, beer, wine, flour and baking powders. The use of chemicals under those conditions creates a safety hazard. PTH eliminates this risk. The same applies to dairies and cheese factories, where it is undesirable to work with chemicals, which may contaminate those products. PTH is smaller and more compact than resin softener, and may easily be disconnected and move to wherever it needed to be.